Follow us on Google News (click on ☆)

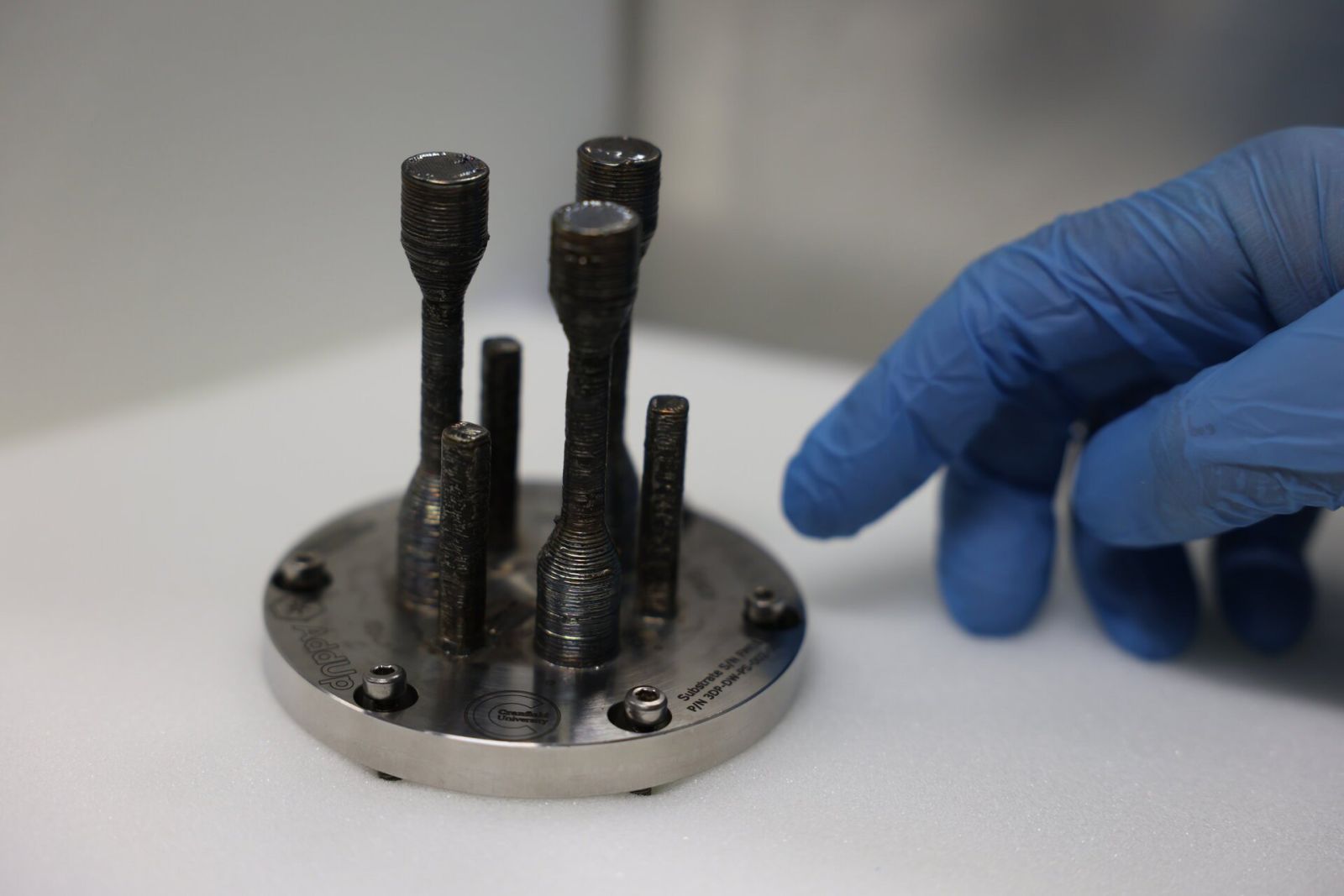

The first metal sample, now back on Earth for analysis.

Credit: ESA

Produced aboard the International Space Station (ISS) using a metal 3D printer developed by Airbus Defence and Space in collaboration with ESA, this sample has been brought back to Earth for analysis. This marks a world first that paves the way for more autonomous space missions.

The printer, installed in the Columbus module by astronaut Andreas Mogensen, has completed several prints since its activation. After initially producing an 'S'-shaped curve, it manufactured two complete samples, marking key milestones in the evolution of this technology.

ESA scientists will now study these samples to understand the effects of microgravity on the printing process. This research is crucial for developing future space missions where 3D printing could play a central role.

This innovation represents a significant step toward self-sufficiency for deep space missions. The ability to manufacture spare parts or tools directly in space would dramatically reduce dependence on resupply missions from Earth.

Metal 3D printing in orbit is just the beginning. The results of ongoing analyses could open the door to even more ambitious applications, such as constructing structures directly in space.

This technological advancement demonstrates the potential of 3D printing to transform how we explore and utilize space. It also marks an important milestone in collaboration between space agencies and industrial partners.

How does metal 3D printing work in space?

Metal 3D printing in space uses a technique similar to Earth-based methods, but adapted for microgravity conditions. A laser melts metal powder, layer by layer, to build the desired object.

The main difference lies in handling the metal powder, which behaves differently without gravity. Special systems are required to contain and precisely direct it.

Printers must be designed to operate under these unique conditions, requiring innovations in materials and design.

This technology enables on-demand production of parts, with designs sent from Earth, reducing the need to transport large stocks of spare parts.