Follow us on Google News (click on ☆)

In everyday life, humans constantly rely on the sense of touch to interact with the world. In contrast, force perception has long been a challenge for robots. Indeed, sensory sensors often come with complex designs and require demanding calibration, limiting their applications.

To overcome these challenges, a team of scientists at LIRMM drew inspiration from natural mechanisms. Building on the properties of human skin and the self-decoupling principle of the Halbach array, they developed a flexible magnetic sensor after two years of research that can distinguish forces in three dimensions. This work was supported by the Key Challenge "Human-Centered Robotics" funded by the Occitanie region and CNRS.

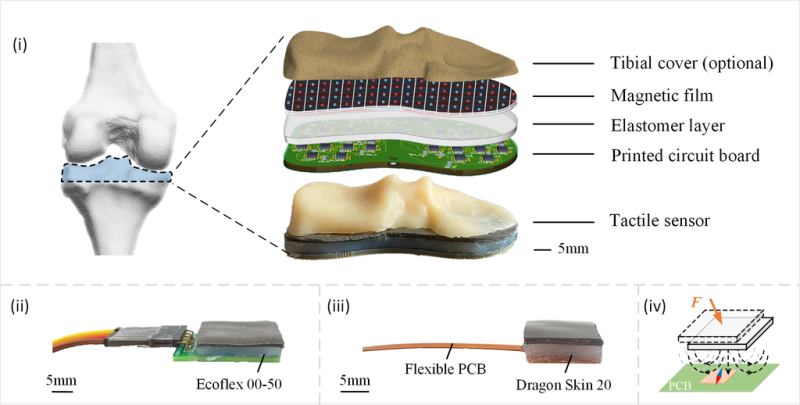

The sensor's design is simple, consisting of three layers. The first layer is a flexible magnetic film that deforms upon contact, altering the magnetic field. An intermediate elastomer layer acts as a cushion, while the final layer is equipped with a printed circuit board and Hall effect sensors that detect changes in the magnetic field. This configuration allows the sensor to independently measure normal (perpendicular) and shear (parallel) forces.

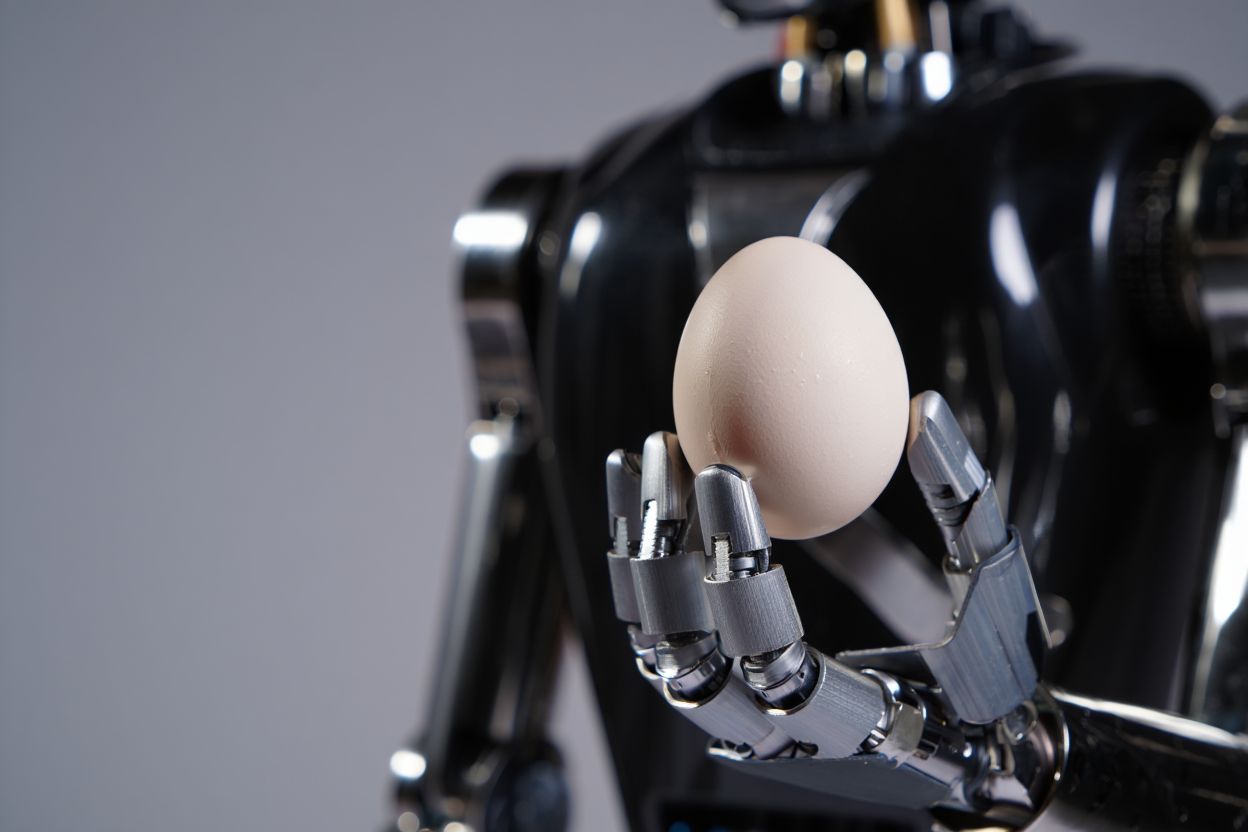

Their article published in Nature Machine Intelligence, showcases several demonstrations of this patented technology. By integrating the sensor into an artificial knee joint, the scientists were able to control how forces are distributed during movement—a result that will help clinicians better understand and treat joint issues. In another experiment, the sensor was used to guide a robot in preparing coffee. By applying slight pressure and sliding motions on the sensor, the robot learned a sequence of movements and reproduced them autonomously, from closing the gripper to pouring water and stirring. The sensor's sensitivity also allows the robot to handle even more fragile objects, such as an egg, without damaging them.

Structure of the sensory sensor (three different designs) and working principle.

© Youcan Yan

The implications of these achievements are significant. In robotics, integrating such sensory sensors could lead to more responsive and adaptive machines capable of performing complex tasks with human-like precision. In healthcare, smart prosthetics or knee braces could benefit from real-time force feedback, combining safety and functionality. Moreover, the sensor's ease of manufacturing and calibration opens the door to its adoption in everyday applications, making advanced tactile sensing accessible outside laboratories.

Looking ahead, the LIRMM team plans to refine the sensor by optimizing its materials and integrating it into more sophisticated systems, including humanoid robots. This innovation promises to bridge the gap between human dexterity and robotic precision, transforming how machines interact with their environment.

For more information:

Yan, Y., Zermane, A., Pan, J. et al. A soft skin with self-decoupled three-axis force-sensing taxels. Nat Mach Intell 6, 1284-1295 (2024). https://doi.org/10.1038/s42256-024-00904-9